Unlock Precision with Our Centrifugal Casting Silicone Mold

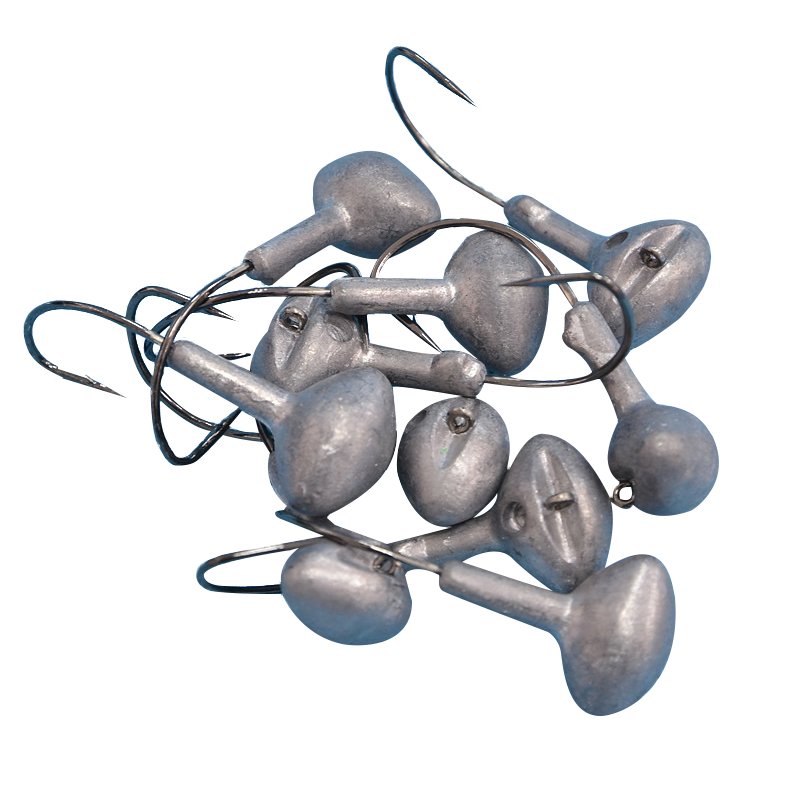

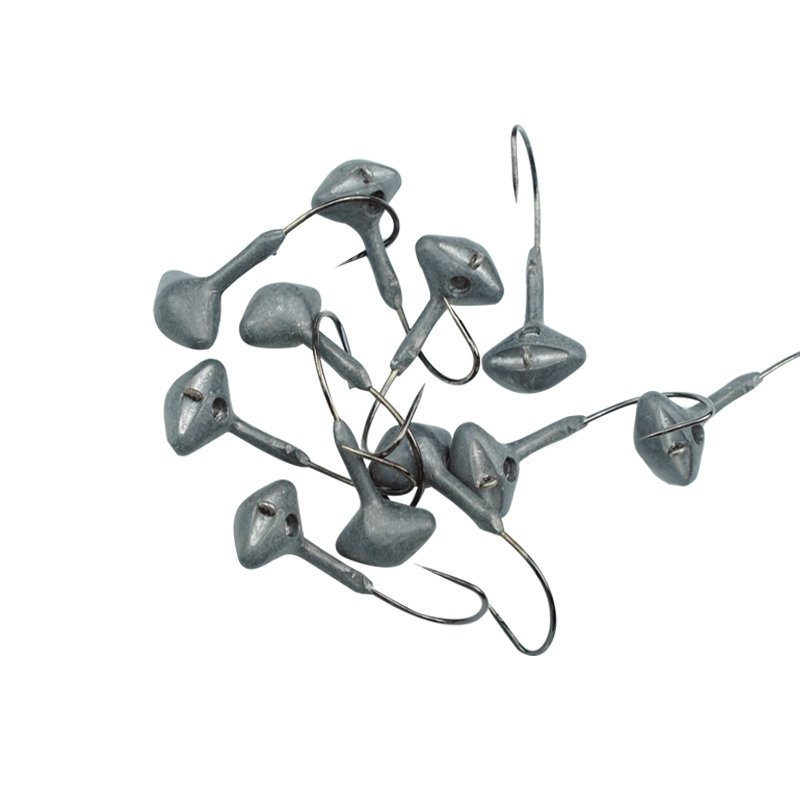

Introducing our innovative centrifugal casting silicone mold, specifically designed for the production of fishhooks. This cutting-edge mold leverages high elasticity and precise replication characteristics to ensure that every fishhook produced meets the highest quality standards. Say goodbye to inconsistent shapes and sizes, and welcome a streamlined manufacturing process that delivers exceptional results.

Custom-Designed Mold for Optimal Results

Every successful fishhook begins with a mold that’s tailored to perfection. Our centrifugal casting silicone mold allows for custom designs, which means you can create cavity shapes that are flawlessly aligned with the desired hook design. The liquid silicone solidifies into a flexible mold that captures even the finest details of the fishhook, including the crucial hook tip and barbs. This attention to detail ensures that your final product not only looks good but performs effectively on the water.

Efficient Production with Minimal Waste

The efficiency of our molds doesn’t stop at design; it extends into production. When molten metals such as stainless steel and carbon steel are poured into the mold, centrifugal force ensures even and rapid filling of the cavity. This process guarantees that every intricate part of the fishhook is precisely formed without any compromise. Once the metal cools and solidifies, the inherent flexibility of the silicone allows for easy demolding, preventing any deformation or damage to the fishhook—a critical factor for maintaining the integrity of your fishing gear.

Experience the benefits of using a centrifugal casting silicone mold for your fishhook production. Enjoy uniform dimensions and stable quality that meet the rigorous demands of the fishing gear manufacturing industry. Get your hands on our state-of-the-art silicone mold and elevate your production capabilities today!

Reviews

There are no reviews yet.