Discover the Extraordinary Properties of Eutectic Alloys

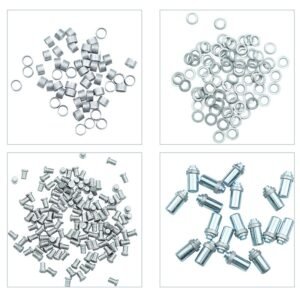

Unlock the potential of eutectic alloy products, revolutionary materials engineered to leverage the low melting points of metals. With melting points typically below 232°C, some of these alloys can even melt as low as 12°C, making them incredibly versatile for various applications. Formulated by expertly combining metals like bismuth, tin, indium, and lead, these alloys present distinctive properties that set them apart from conventional materials.

Applications in Safety and Industry

Eutectic alloys play a vital role in the safety sector, prominently utilized in the manufacturing of circuit fuses and thermal-sensitive components for fire sprinkler systems. By rapidly melting at high temperatures, they provide effective overload protection and quick fire warnings, ensuring safety in critical situations. In industrial environments, low-melting-point molds and fixtures are extensively used for precision casting and electronic soldering. This process not only guarantees the accuracy of machined workpieces but also minimizes material losses, enhancing both efficiency and productivity.

Medical and Environmental Advantages

In the healthcare field, eutectic alloys are invaluable for creating radiotherapy positioning molds. These molds offer patients precise fixation solutions, allowing for a blend of comfort and accuracy during treatment. As environmental concerns intensify, the integration of non-toxic and high-performance eutectic alloy products is on the rise, establishing them as the mainstream choice in material science. With ongoing advancements, these alloys are anticipated to make significant contributions to emerging sectors such as thermal management for new energy batteries and smart temperature-control devices.

As the application scope of eutectic alloys broadens, their benefits become increasingly evident. By combining safety, precision, and environmental awareness, these alloys are poised to revolutionize numerous industries, making them a smart choice for your product needs. Dive into the future with our eutectic alloy solutions — where safety meets innovation.

Reviews

There are no reviews yet.