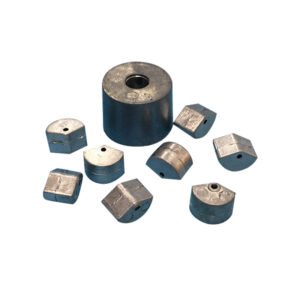

Various shapes and weights of lead, tin, zinc alloy products can be designed and sampled according to customer needs, such as various handicraft ornaments, exquisite jewelry, lead fish, lead pendants, lead counterweights, etc

Ordering Notice:

1. Price: This price is a reference price, and specific prices can be communicated with customer service

2. Product material: CB99.995Pb

3. Regarding the product: Customized production based on drawings and samples is available

4. Product quality: Customers can come to our factory for a visit, or if there is an intention to cooperate, we can send you samples of similar products.

5. Product Design: We are a manufacturer specializing in the production of hardware products. As long as you have drawings or dimension drawings/styles, we can customize them for you.

6. Product grade: Customers who want to customize products need to inform us in advance of the surface treatment effect they require, so that our quotation can be more accurate.

7. Regarding quotation: Customers need to provide product samples or dimension drawings, as well as weight, surface treatment requirements, and whether tax and shipping are required.

If there are only pictures and no specific size drawings, our production process is as follows: product drawing design – drawing confirmation – first version layout – first version sample confirmation – steel mold opening (7-15 days according to difficulty level) – trial mold sampling – sample confirmation – bulk production – shipment

9. If there are design drawings, the steel mold can be directly opened – trial mold sampling – sample confirmation – bulk production – shipment

10. Minimum order quantity: (depending on product size)

The production process of alloy products:

Product drawing design – Drawing confirmation – Prototype layout (usually 1.5 times) – Prototype sample confirmation – Steel mold opening (10-25 days according to difficulty level) – Trial mold sampling – Sample confirmation – Bulk production – Shipping

Advantages of Die Casting Process:

1. Products with fine workmanship, clear edges and corners, and high requirements for pattern and text clarity, are less prone to deformation during polishing, have fewer sand holes, are better electroplated, and are less prone to scratches.

2. High efficiency in mass production

3. High precision requirements for size and weight

Advantages of centrifugal casting process:

1. Low mold cost

2. Suitable for products with small quantities, large sizes, and complex patterns

Lead fish and lead weight block products

Lead fish and lead weight block products

Dongguan Chang’an Bingkai Metal Jewelry Material Factory (subsidiary: Dongguan Zhuokai Jewelry Machinery Co., Ltd.) has been engaged in the production of alloy jewelry materials, jewelry machinery, and jewelry processing services for many years. From the production of jewelry raw materials to advanced production equipment, from standardized equipment to advanced customer personalized solutions, we use our accumulated experience and leading technology in this field to continuously innovate and surpass, providing our customers with the most valuable products and satisfactory services. We welcome your trust with the best quality, most favorable price, and most sincere service!

Company Objective: Strive for excellence, cooperate for win-win results

Business philosophy: reputation first, technology first, customer first

Business project:

1. Metal jewelry, handicrafts, shoe decorations, shoe buckles, and other alloy materials, environmentally friendly tin alloys, low-temperature zinc alloys, lead tin alloys (lead antimony alloys), scheelite alloys, lead fish, lead pendants, and lure bait

2. Magnesium zinc alloy, fusible alloy (melting point 47-200 degrees), tin bismuth alloy, mold alloy, solder ring, fusible plug

3. Alloy jewelry machinery: fully automatic centrifugal casting machine, molding machine, furnace, dryer, environmentally friendly water curtain cabinet, oven and polishing equipment, etc;

4. Small die-casting machines, high-speed die-casting machines, vertical die-casting machines, lead product die-casting machines;

5. Alloy jewelry molds: various types of AB rubber molds, as well as high-temperature resistant imported rubber molds;

6. Alloy soldering flux: Zinc alloy special welding wire, alloy soldering water;

7. Undertaking: Processing of alloy jewelry and handicrafts;

Related products

-

Polishing Machine

Lead fish and lead weight block products

-

Polishing Machine

Lead fish and lead weight block products

-

Polishing Machine

Lead fish and lead weight block products

-

Polishing Machine

Lead fish and lead weight block products

Recently Viewed Products

-

Polishing Machine

Lead fish and lead weight block products

Reviews

There are no reviews yet.