Eutectic alloy, also known as low-melting alloy or mold alloy, is an alloy made of elements such as bismuth, lead, tin, and cadmium.

Melting point:

below 232℃ (melting point of tin)

Element composition:

bismuth, lead, tin, cadmium, as well as indium and gallium, etc

Classification:

Eutectic alloy, Non-eutectic alloy

Scope of application:

1) Fusible alloy is used in nuclear magnetic resonance equipment, primarily as specialized blocks of specific shapes.

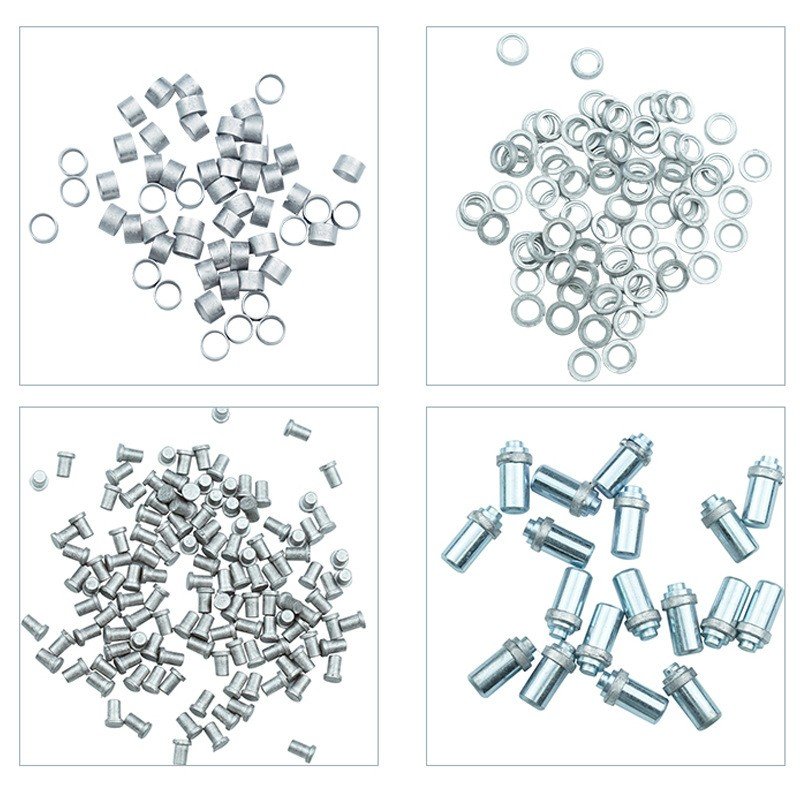

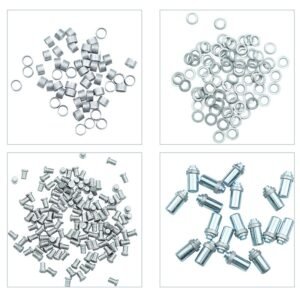

2) Fusible alloys can be conveniently used for casting and mold making, producing molds for special products, and casting special products.

3) Fusible alloys are widely used in electronic and electrical automatic control, serving as thermal sensors and safety materials. Customers can, according to their respective production needs, use temperature-controlled fusible alloys to manufacture thermal sensors of various shapes, specifications, and different melting points that meet temperature control requirements.

4) Fusible metal is used as a filler when bending metal tubes.

5) When making metallographic specimens, fusible metals serve as inlays.

6) It can be used as a sensing component for safety relief devices of gas cylinders and cylinder valves, such as safety relief devices for acetylene cylinder valves, natural gas cylinder valves, and other industrial gases.

Our company can customize fusible alloys with various melting points and shapes

Reviews

There are no reviews yet.