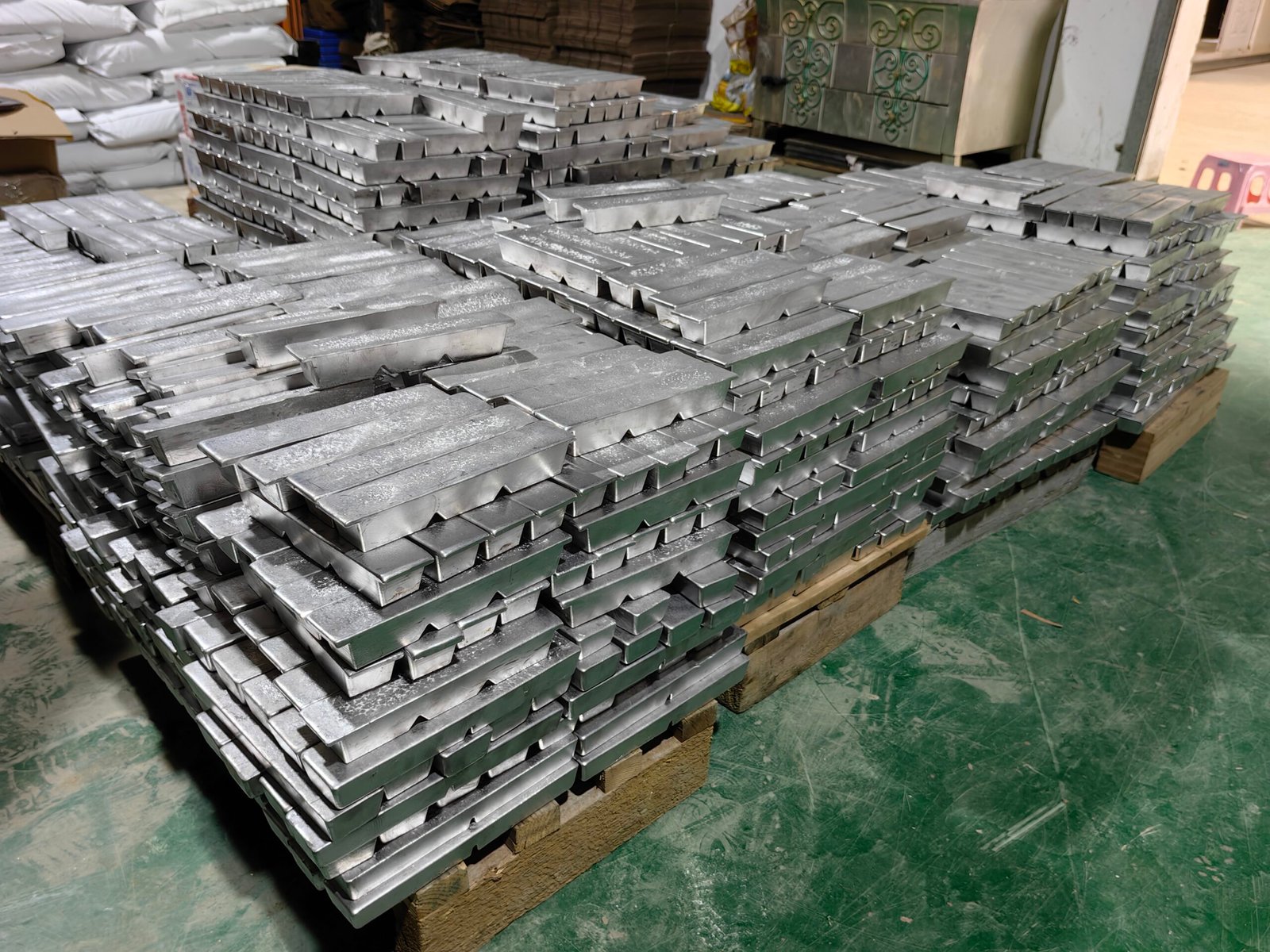

What is Eutectic Alloy?

Eutectic alloy refers to a unique type of metal alloy that boasts a melting point below 232°C. It is primarily composed of low-melting-point metals, with bismuth, lead, and tin being the most common components. This allows for a remarkable versatility; the melting point can be tailored based on the composition of the alloy. For instance, Wood’s alloy, which is a type of eutectic alloy, has an impressive melting point of just 70°C, making it particularly useful in specific applications.

Properties and Applications

Eutectic alloys are known for their excellent molten fluidity and minimal condensation shrinkage. These properties make them ideal for various uses in industries such as mold making, the production of thermal-sensitive elements in fuses, and low-temperature welding applications. Their ability to remain in a liquid state at lower temperatures allows for precision in molding and manufacturing processes that require intricate detailing.

Environmentally Friendly Innovations

In recent years, the shift towards more sustainable and eco-friendly manufacturing processes has led to the development of bismuth-tin-indium alloys. These environmentally friendly alternatives have begun to replace traditional lead-based materials, enhancing safety without sacrificing performance. As a result, eutectic alloys are becoming increasingly common in precision manufacturing sectors, where both material integrity and safety are paramount.

In summary, eutectic alloys offer a blend of versatility, low-melting properties, and environmentally conscious options that make them a valuable investment for any manufacturing business. Embrace the future of metal alloys and explore how incorporating eutectic alloys can enhance your products and lead your operations towards a more sustainable path.

Reviews

There are no reviews yet.