Introduction to Fusible Alloy Fittings

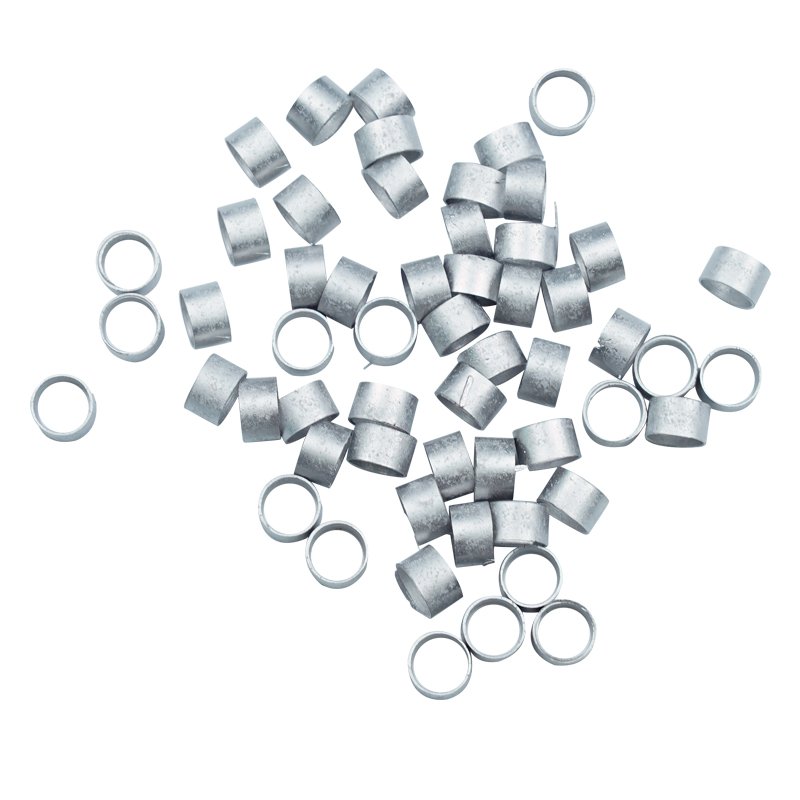

Fusible alloy fittings are highly versatile components essential for various industries, ranging from electronics to manufacturing. These fittings are crafted by melting and combining low-melting-point metals, including bismuth, tin, and indium, resulting in products that offer unique advantages in precision molding and thermal applications.

Unmatched Properties and Performance

What sets fusible alloy fittings apart is their characteristic melting points, typically below 232°C. A prime example is the Wood’s alloy fitting, which melts at only 70°C, making it an ideal choice for applications requiring controlled melting temperatures. Once heated, these fittings provide exceptional fluidity in their liquid state, ensuring efficient filling of molds, which is crucial for precision engineering.

The small solidification shrinkage of fusible alloys further enhances their usability, as this property minimizes defects and improves the overall quality of molded products. This means that when it comes time to cool and solidify, you can count on a reliable fit without the headaches associated with traditional materials.

Applications and Benefits

Fusible alloy fittings are used in a variety of applications, including soldering, casting, and as safety mechanisms in systems that require thermal control. Their ability to melt at low temperatures makes them ideal for delicate components that cannot withstand high heat. Moreover, the compatibility of these fittings with different metals ensures seamless integration into existing processes, offering an efficient and functional solution.

Overall, opting for fusible alloy fittings means investing in reliability and precision. Whether you’re in the electronics field, manufacturing, or looking for innovative thermal management solutions, these fittings deliver both performance and quality.

Reviews

There are no reviews yet.