Unlock the Potential of Spin Casting with Rotary Mold Silicone

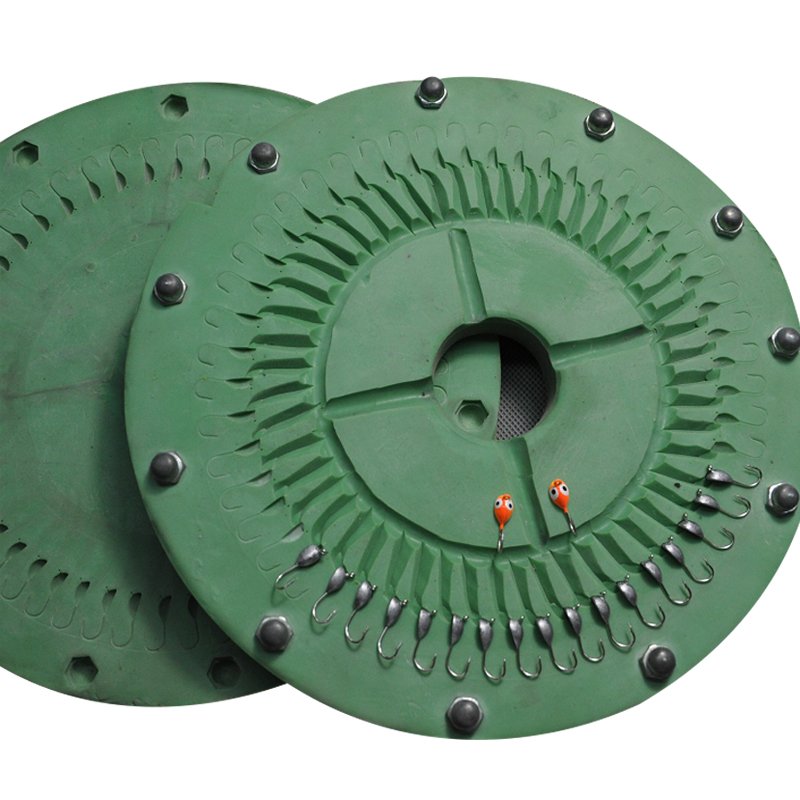

Introducing Rotary Mold Silicone—a cutting-edge silicone rubber material meticulously designed for the Spin Casting process. This innovative product is not just a mold; it’s an essential tool for artisans and manufacturers who aim for perfection in their casting projects. With its unique properties, Rotary Mold Silicone delivers molds that feature exceptional elasticity and temperature resistance, making them ideal for various applications.

Why Choose Rotary Mold Silicone?

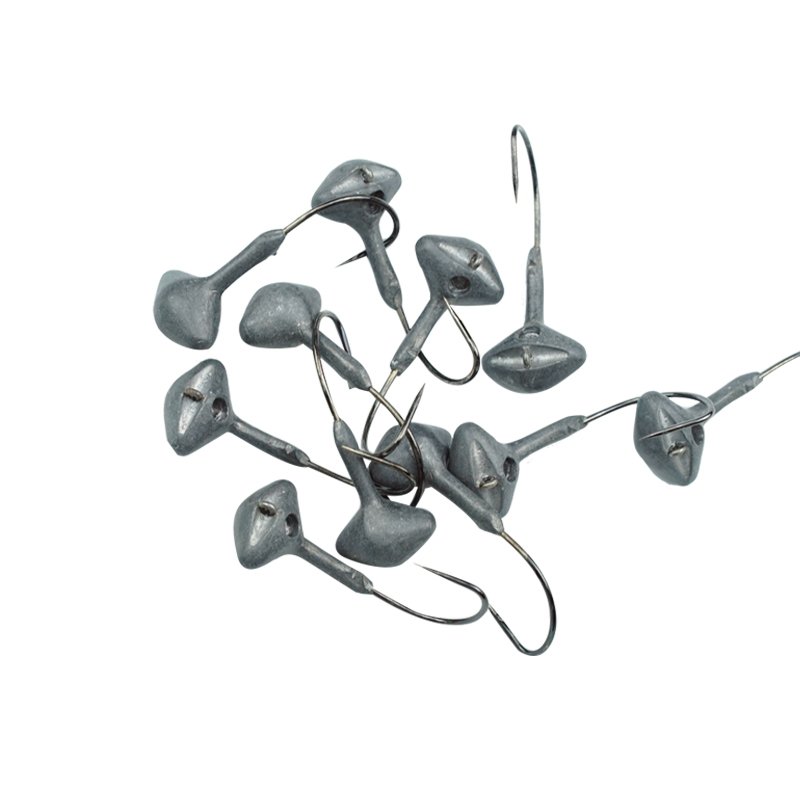

This versatile silicone material stands out in the world of casting through its unparalleled advantages. The centrifugal force generated during the rotation process allows materials such as molten metal and resin to flow smoothly into the mold cavity, ensuring an even fill. This leads to detailed and accurate replication of complex designs, making it the go-to choice for jewelry makers and manufacturers of precision parts.

Simple Demolding for Complex Shapes

One of the noteworthy benefits of Rotary Mold Silicone is its remarkable flexibility, which facilitates easy demolding of intricate structural components. Unlike traditional molds, which can be rigid and cumbersome, this silicone ensures that even the most detailed designs can be extracted effortlessly. This feature not only saves time but also enhances the quality of the final products, allowing for a smoother production process overall.

Moreover, Rotary Mold Silicone is widely used in both mass casting and customized production settings. Whether you are manufacturing a limited series of bespoke jewelry or large quantities of precision components, this silicone material adapts to your needs. Elevate your casting process with Rotary Mold Silicone and experience efficiency, flexibility, and high-quality results in every project.

Reviews

There are no reviews yet.