Maximize Efficiency with Vertical Precision

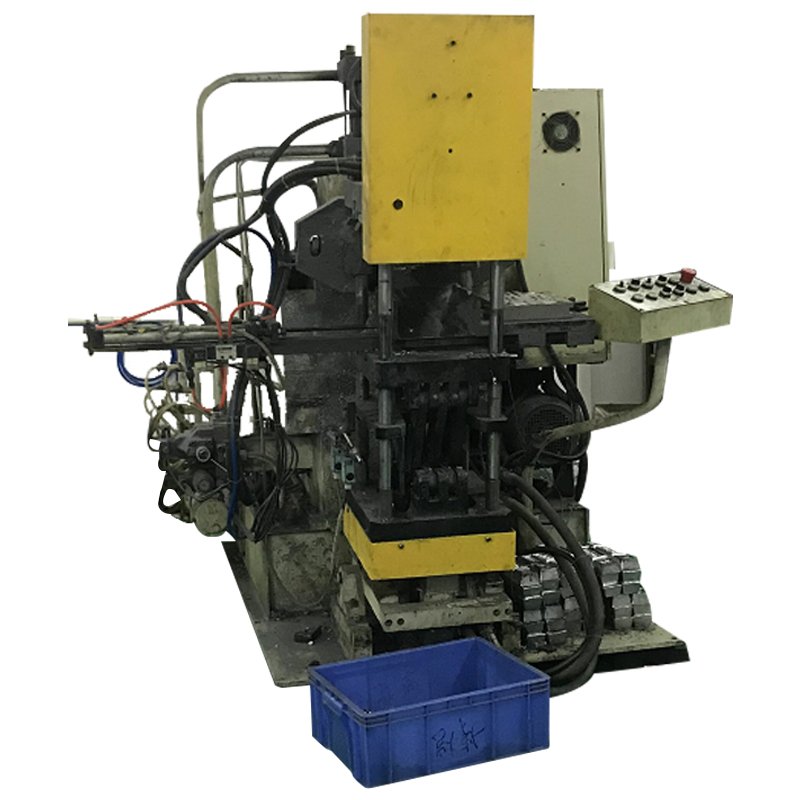

The Vertical Die-Casting Machine stands at the forefront of metal-forming technology, designed for those who prioritize both efficiency and precision. Featuring a vertically oriented injection punch and mold operation, this machine offers a unique approach to die-casting that minimizes waste and maximizes output.

Superior Design for Complex Castings

Unlike traditional horizontal die-casting machines, our vertical model does not require a separate residue removal mechanism. This innovative design significantly reduces metal waste, making it an eco-friendly choice for manufacturers. The vertical injection method allows for the production of intricate parts with center holes and complicated internal structures, meeting the stringent demands of industries such as electronics and aerospace.

Enhanced Operational Advantages

With a focus on high-speed operation, the Vertical Die-Casting Machine is engineered for optimal performance. During casting, molten metal is injected into the mold cavity quickly and efficiently, ensuring a high-quality finish with minimal defects. Once the metal cools and solidifies, the machine opens the molds vertically, streamlining the extraction process. This user-friendly interface not only speeds up production times but also ensures that quality standards are consistently upheld.

In summary, the Vertical Die-Casting Machine is an exceptional investment for any facility looking to enhance its manufacturing capabilities. Providing a unique combination of efficiency, precision, and ease of use, it is the preferred solution for industries that require high levels of accuracy in their components. Embrace the future of metal forming technology today with our highly effective vertical die-casting machine.

Reviews

There are no reviews yet.